CAPACITIES AND RESOURCES

R&D

Production & Facilities

HPAPI

Fermentation

EXPERTISE

Differentiating Technologies

Know-how

R & D

Farmhispania Group companies have more than 60 scientists working in 5 different laboratories focused on process development including High Potency (HPAPI), fermentation and continuous improvement / operational excellence.

We focus on scale up, efficiency, safety and environmentally friendly new processes, from grams to hundreds of grams, using classical process chemistry tools together with the most advanced technologies and methodologies. Our scientist routinely utilises the principles of Design of Experiments (DoE) coupled with reaction carousels and Quality by Design (QbD), to get better results as a combination of chemical expertise, process understanding and business driven approaches.

scientists

different laboratories

Pilot plant and kilo-lab equipment includes vessels from

Our R&D activities cover three different areas: process development, analytical development and pilot plant. These areas involve 60 scientists.

Farmhispania Group has 5 different laboratories at our sites in Montmeló and Zaragoza where we carry out process and analytical development, scale up of API’s, HPAPI’s and fermentation products.

» Read more

We have two fully equipped laboratories for process and analytical development at both sites. Our on-site chromatography equipment includes HPLC with different detectors (UV/Visible, Evaporate Light Scattering, Electrical conductivity, Refraction Index and PDA), Preparative HPLC, Preparative MPLC, UPLC (UV/Visible and Xevo QToff detectors) and GC.

In addition, we have a HPAPI dedicated laboratory at our Montmeló site with 4 chemistry gloveboxes and fume-hoods capable of working up to hundreds of grams.

Furthermore, we have a biotech laboratory at our Zaragoza site. It is outfitted with all the necessary equipment to carry out up-stream and down-stream fermentation development.

Finally, we have a fifth laboratory where we carry out continuous improvement and operational excellence tasks, troubleshooting and testing new production technologies.

» show less

Farmhispania Group has at both sites pilot plants and kilo-labs to scale up manufacturing processes and carry out cGMP manufacture of API´s for Clinical Trials and commercial supply.

» Read more

Our equipment includes: vessels from 5 to 1000 L, temperature range from -70 to 200 ºC, filtration equipment, centrifuges and a wide range of handling equipment to mill, dry and lyophilise the bulk product.

For HPAPI, Farmhispania Group has recently opened a kilo-HPAPI area where we have two lines with vessels from 10 to 63 L, including Aurora filter and a tray drier.

» show less

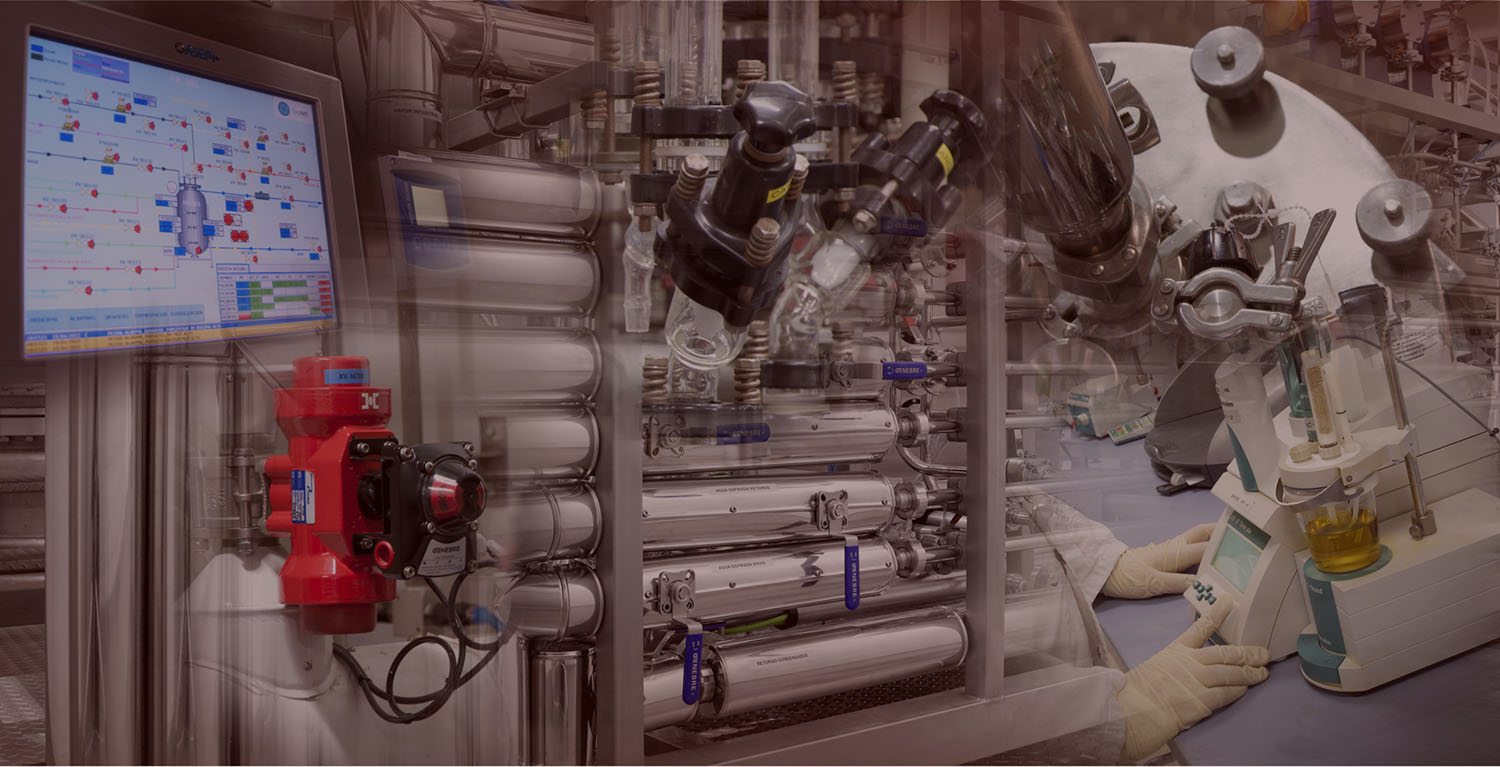

Production & Facilities

Farmhispania Group consists of two companies in Spain: Farmhispania (Barcelona) and Rolabo (Zaragoza). With more than 250m3 of reaction capacity and the latest technology in high potency (HPAPI) and fermentation, our plants and teams are equipped to carry out a wide range of chemical reactions under strict cGMP compliance.

» Read more These sites have been successfully inspected by worldwide National Health Agencies such as FDA, AEMPS, KFDA and PMDA. Farmhispania Group develops and manufactures a diverse range of API’s, advanced intermediates and building blocks. Furthermore, Farmhispania Group provides PR&D and manufacturing services to support clinical trials and commercial supply. In recent years Farmhispania Group has carried out a multi-million year on year reinvestment in facilities and new technologies, including highly potent, fermentation, hydrogenation, flow chemistry and wet milling capabilities. » show less

cGMP manufacturing sites in Spain

Large scale equipment includes vessels up to

HPAPI

The HPAPI Technical Centre, located at the Montmeló site, has different facilities to develop, scale up and cGMP manufacture highly potent API including cytotoxics with an OEL below 30 ng/m3, from a few small grams to multi kilograms.

» Read more The HPAPI Technical Centre has: Farmhispania Group carry out hazard assessments to appropriately categorise API/HPAPI in our banding system on the basis of the toxicity and potency. This categorisation is performed using comprehensive analysis of reported data, properties, literature sources available and on-line data bases and QSAR “in silico” approach. The engineering controls and handling practices are established on the basis of the risk assessment conducted on a case-by-case basis. » show less

Fermentation

Highly potent fermentation capabilities have been launched at our Zaragoza site.

These capabilities include complete equipment to the upstream and downstream parts of the fermentation process, from small scale to large scale production. Currently we are carrying out aerobic fermentation of complex potent products.

» Read more Our facilities include: Large scale downstream equipment, including thin-film evaporating technology and large scale column chromatography. » show less

Differentiating Technologies

As molecules and active ingredients evolve so does process development technologies and methodologies. With the aim of keeping Farmhispania Group up to date on any breakthrough in innovation, our teams continuously incorporate new and differentiating technologies to develop more complex, better controled and more profitable processes.

» Read more

Wet milling of products has the potential to achieve the particle size necessary for drug product formulation without the need for a final grinding operation of the dry powder.

Farmhispania Group has introduced this technique at our Zaragoza site for the treatment of fermented biomass and it is being introduced at our Montmeló site.

» show less

» Read more

Continuous-flow technology involves the continuous introduction of a stream of chemical reactants into a tube reactor or a microreactor to yield a desired reaction product on a continuous basis. This offers advantages compared with traditional batch manufacturing, such as greater optimization and control of the process and improved safety

» show less

» Read more

Farmhispania Group introduced this lyophilisation technology at our Montmeló site 15 years ago. 7 different freeze drying suites capable of producing metric tons quantities of bulk API per year. This long experience allows Farmhispania Group to support our customers with complex products.

» show less

» Read more

Farmhispania Group has large scale preparative HPLC systems to permit the purification of products using different detectors as a fraction trigger and valve configurations to accommodate virtually any number of single or multiple column schemes.

Large scale chromatography has been used in Farmhispania Group for more than 7 years for the purification of API’s. Farmhispania Group has different HPLC equipment, with columns from 110 to 300mm diameter, which allows us to cover different production ranges, from grams to kilograms.

» show less

Know-how

Over the 40 years of its history, Farmhispania Group has gained deep experience and know-how in developing and scaling up manufacturing processes for API’s. This experience and know-how is broadly represented in the following areas:

years of history

» Read more

Process safety assessment is focused on preventing any accidents in our chemical process facilities dealing with hazardous materials.

Our process safety assessment includes literature and data base screening, “in-silico” reaction heat estimation (Chetah®), experimental decomposition heat estimation (DSC) and external RC1 / ARC calorimetric studies.

It is routinely applied to all processes and steps prior to scale-up and industrialisation.

» show less

» Read more

Potential Genotoxic Impurities (PGI) assessment is performed internally to determinate which substances (impurities, degradants, carry-overs, etc) are to be considered PGIs and therefore controlled/justified its absence or purge during the manufacturing process.

The PGI assessment include literature and public data bases, QSAR Toolbox® and statistical QSAR (Quantitative Structure–Activity Relationship) prediction software to determine its potential genotoxicity and Teasdale purging factor methodology and/or trace level analytical methods to demonstrate and justify its absence in APIs.

» show less

» Read more

Quality by Design (QbD) approach and concepts are progressively being adopted at Farmhispania Group to support process development and final DMF submission of API’s.

The main benefits are rational process design and development, better process understanding and straight forward process optimisation in line with the new regulatory trends for process validation.

Main QbD work-flow and tools already incorporated into Farmhispania Group include: CQA (Critical Quality Atribute) definition, preliminary risk assessment by Cause-Effect analysis (Ishikawa and FMEA type analysis) , Factors ranking , multifactorial studies by statistical Design of Experiments (DoE) with Modde ® software assistance for process design (screening and optimization) and final modelisation with confirmatory runs . All these supported by multireaction carousels for experiments in parallel.

» show less

» Read more

API/HPAPI categorisation is performed when submitting any new project to technical evaluation or feasibility study. The goal of this study is to ensure maximum product and operator safety, to define appropriate handling, cleaning, operator protection (engineering controls, PPE) and potential cross-contamination risks.

API/HPAPI categorisation is performed using comprehensive analysis of reported data/properties, literature sources available, on-line databases and QSAR “in silico” approach.

» show less

» Read more

Our engineering team located at both sites are in charge of designing and customising new facilities or to fit the existing ones to locate or transfer new manufacturing processes.

» show less

We use our own and third-party cookies to analyze the use of the website and show you information related to your preferences based on a profile created from advertising of your browsing habits (for example, pages visited). COOKIES POLICY

Configure DenyAccept allWe use third-party cookies to improve user experience and to provide a better service, as well as to analyse navigation habits for statistical purposes. You can change the cookie configuration of your navigator at any moment. Upon pushing the accept button, you agree to the use of these cookies. You can obtain more information or know how to change the configuration by clicking on the Cookies Policy incorporated in this website.

They are strictly necessary to manage and operate the web and for the services expressly requested by the user. They allow the user to navigate through the website or application and the use of the different options or services that exist in it. For example, controlling traffic and data communication, identifying the session, accessing restricted access web parts, remembering the elements that make up an order, submit the request for registration or participation in an event, using security features during navigation and storing content for the broadcast of videos or sound. or participation in an event, using security features during navigation and storing content for the broadcast of videos or audios.

Also belonging to this category, due to their technical nature, are those cookies that allow the management, in the most efficient way possible, of the advertising spaces that, as another element of design or "layout" of the service offered to the user, the editor has included in a web page, application or platform based on criteria such as the edited content, without collecting information from users for other purposes, such as personalizing that advertising content or other content.

They allow the user to access the service with some general characteristics predefined in its terminal or that the user himself defines. For example, the language, the type of browser through which you access the service, the selected content design, the geolocation of the terminal and the regional configuration where the service is accessed from.

Are those cookies that, treated either by us or by third parties, allow us to quantify the number of users and thus perform the measurement and statistical analysis of the use made by users of the service. For this purpose, the navigation and behavior of a user on the website is analyzed in order to introduce improvements based on the analysis of the data usage made by users of the service.

Are those that store information on user behavior obtained through the continuous observation of their browsing habits, which allows the development of a specific profile to display advertising based on the same.

You can read about our cookies and privacy settings in detail on our Privacy Policy Page

Clicking "Save settings" will save the cookie selection you have made. If you have not selected any option, clicking this button will be equivalent to rejecting all cookies.